Our legacy is built on the foundation of integrity, safety, and environmental responsibility.

Our dedicated team of professionals is driven by a shared vision to meet the energy needs of a rapidly evolving world.

Driven by a relentless pursuit of excellence, our mission encompasses the responsible sourcing, refining, and distribution of petroleum derivatives. We aim to set new standards of quality, safety, and efficiency in our operations, all while fostering a culture of continuous improvement and adaptability to the changing energy landscape.

Our vision is more than a distant horizon it’s a guiding light that propels us to reimaging the potential of petroleum derivatives and reshape the energy narrative. We are committed to turning our vision into reality, to revolutionize energy practices, and to leave an indelible mark on the world as a force for positive change.

Do the right thing.

Keep your word.

Make things better.

Shandong HongYu Trading Co is a well-established investment management company. The company has a strong focus on emerging markets, which offer the potential for high returns.

Focusing on emerging markets for a company dealing in petroleum products and derivatives presents a strategic approach that can yield significant growth opportunities and diversification.

Our vision is of an increasingly interconnected and prosperous world where physical commodities pass seamlessly from their points of origin to points of need. We add value to the global trade in natural resources by delivering exceptional service and performance across the supply chain. We source raw commodities from miners, oil and gas producers and match the processing requirements of refineries, smelters and liquefaction plants. We supply end-users, including state agencies, manufacturers, utilities, power plants, energy retailers and construction companies, with the processed commodities they need.

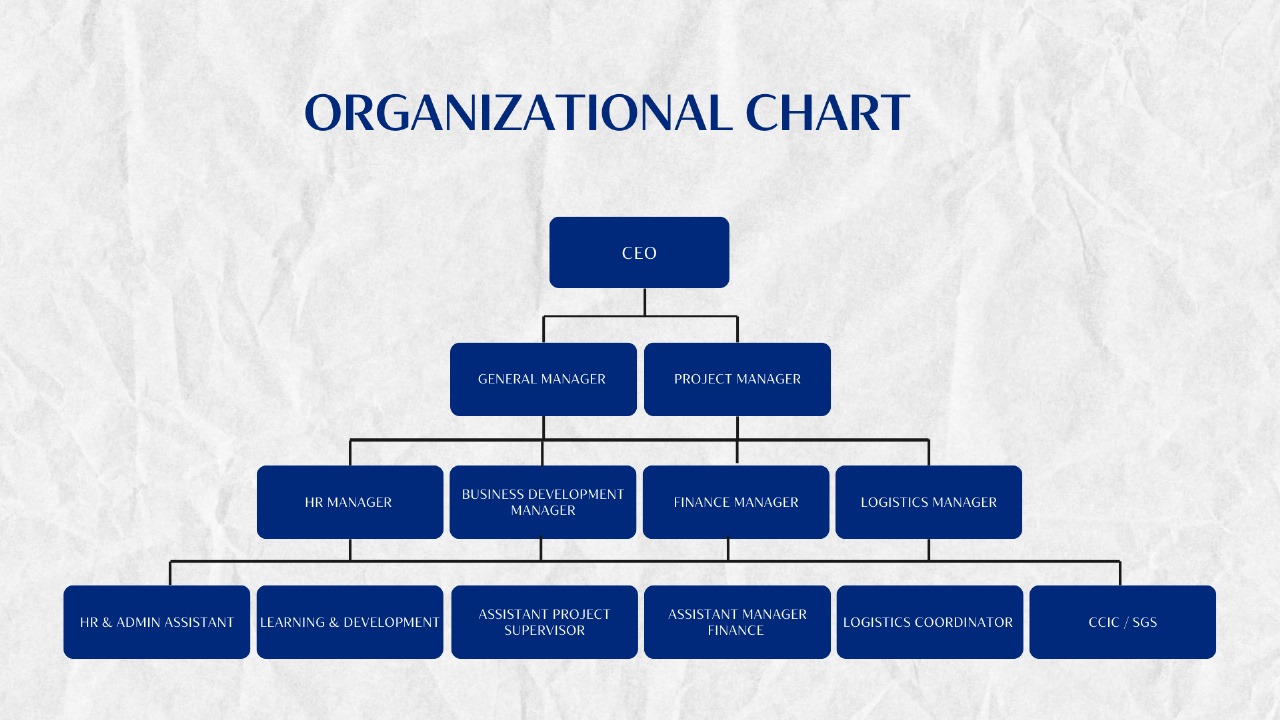

Our integrated logistics and supply chain strategies enable us to navigate the intricate landscapes of petroleum derivatives and investment with precision. By ensuring the seamless movement of products and information, we uphold our mission to deliver value to customers, partners, and investors while contributing positively to both industries and the environment.

Logistics provides shipping and freight services to various commodity trading teams and third-party clients.